The two primary objectives in a domestic hot water plumbing system are:

• Heat the water in a cost-effective manner.

• Deliver the water at an appropriate temperature to the plumbing fixtures.

There are many options to accomplish both objectives using a wide variety of energy sources. One approach that is quickly gaining market share is based on heat pump technology. When applied properly, heat pump water heaters (HPWH) require approximately 60% less energy than electric-resistance water heaters and have the potential to reduce carbon emissions when compared to gas water heaters, according to the Pacific Northwest National Laboratory.

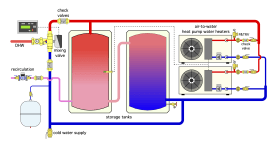

There are many opportunities to integrate HPWHs in both residential and commercial domestic water systems. Identifying those opportunities and planning the installation accordingly will maximize energy efficiency without negatively affecting the comfort and convenience consumers expect.

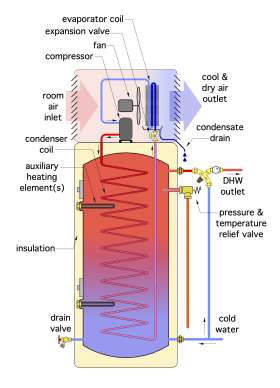

Residential HPWHs typically use an air-to-water heat pump assembly mounted on top of a tank. The condenser coil for the heat pump is either submerged in the tank or wrapped around it. Figure 1-1 shows the concept. Most HPWHs used in residential applications also have auxiliary electric-resistance heating elements that supply heat during periods of high demand.

Using a standard refrigeration cycle, HPWHs transfer heat from air surrounding them, or sometimes from outside air, into the tank water. Because they mostly move heat rather than create it, HPWHs can provide the same amount of domestic hot water as an electric-resistance water heater using only 25 to 33% of the electrical energy input.

The U.S. Department of Energy and ENERGY STAR® recommend replacing water heaters every ten years. Based on this, the opportunity to reassess the best water heating system for a given building is a relatively frequent recurring cycle. In the average North American home, the original water heating system may be replaced many times throughout the life of the building.

When a building’s water heater fails and a replacement is needed as soon as possible, the least complicated approach is a “like-for-like” replacement, since it restores hot water service quickly. However, these ASAP swaps often omit consideration of new technology and energy-saving options.

Changing a standard water heater to a HPWH is best evaluated before an emergency. By considering the potential for improvement, owners can achieve highly energy-efficient domestic hot water heating using HPWHs.

There are advantages and limitations to every type of water heating device. The underlying energy-efficiency potential of heat pump technology creates a high potential to save energy in the domestic water heating segment. This issue of idronics will assist in evaluating HPWH technology in both retrofit and new construction applications.