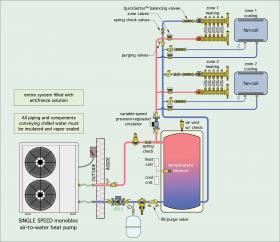

The system shown in Figure 8-4 provides heating and cooling to two zones. The system can only operate in one mode (e.g., heating or cooling) at a time. The buffer tank and heat pump are shown in heating mode.

The heating and cooling source is a single speed monobloc air-to-water heat pump. The buffer tank is piped in a 3-pipe configuration and is used in both heating and cooling modes. The entire system operates with a solution of propylene glycol antifreeze.

In heating mode, a variable-speed pressure-regulated circulator supplies two independent zones of radiant panel heating. Flow through each manifold station is controlled by a zone valve. Each manifold station also has a flow balancing valve. The zone valves to the fan-coils remain closed during heating mode.

In cooling mode, the same circulator supplies two independently controlled fan-coils. Each fan-coil circuit has a flow balancing valve. The zone valves to the heating manifold stations remain closed during cooling mode.

During heating mode, the heat pump and its associated circulator are turned on and off based on an outdoor reset controller that monitors the temperature at the mid-point of the buffer tank. This control action is independent of any call for heat from the room thermostats. The warmer the outdoor temperature, the lower the target temperature calculated by this controller. The maximum water temperature during heating mode is 110ºF. The minimum temperature is 80ºF.

The reset controller operates on a 10ºF differential centered on the target temperature. These temperatures allow the heat pump to operate at a relatively high COP. During cooling mode, the heat pump and its associated circulator are turned on and off based on a temperature setpoint controller that monitors another sensor at the midpoint of the tank. The heat pump is turned on when the tank temperature is 60ºF or higher. The heat pump is turned off when the tank temperature drops to 45ºF. The heat pump operates independently of calls for cooling from the room thermostats. Spring check valves are used to prevent reverse thermosiphoning from the tank, and to limit chilled water migration into the heating portions of the distribution system.

A magnetic dirt separator is used to protect the heat pump and high-efficiency circulator for dirt and iron oxides.

21st century refrigeration techniques now make it possible for air-source heat pumps to operate in cold winter climates, with significantly improved performance compared to earlier-generation heat pumps. By combining low-ambient air-source heat pump technology with the versatility and high distribution efficiency of modern hydronics, designers can create systems for unsurpassed heating and cooling comfort, as well as domestic hot water production. Those systems are ideally suited for use with renewably sourced electricity, carbon reduction goals and “net zero” building projects. When properly selected and applied, low-ambient air-to-water heat pumps can approach the performance of geothermal heat pump systems at significantly lower installation cost and complexity. Air-to-water heat pump systems offer hydronic heating professionals a means of responding to evolving market trends and constraints without compromising quality, comfort or efficiency.