PREFACE

Modern hydronics technology is a “media” that skilled designers can use to create an appropriate heating or cooling solution for almost any building. The versatility of modern hydronics technology is unmatched by any other means of heating or cooling buildings.

This section highlights the benefits of modern hydronic systems, both to those designing and installing systems, and to the occupants of buildings that are heated or cooled using hydronics technology. It is essential that heating and cooling professionals understand the basis for these benefits and effectively communicate them to those who are trying to select a means of heating or cooling for their building.

COMFORT

Every heating system affects the health, productivity and general well-being of numerous people over many years. The ability of that system to provide thermal comfort is of paramount importance and should be the primary objective of any heating system designer or installer.

Few people don’t appreciate a warm comfortable house on a cold winter day. A place that helps them forget about snow, ice and wind as they walk in the door. A place that encourages a sense of well-being and relaxation.

Still, the average North American homeowner spends little time thinking about his or her heating system. Many view such systems as necessary but uninteresting. When construction budgets are strained, it is often the heating system that gets compromised to save money for other, seemingly more important amenities. In many cases, it is the homebuilder rather than the homeowner who selects the heating system. Builders often have different priorities from those who will live with, maintain and pay for the operation of that system.

In many cases, people who have lived with uncomfortable heating systems don’t realize what they have been missing. Many would welcome the opportunity to live or work in truly comfortable buildings and would willingly spend more money, if necessary, to do so. Successful heating professionals take the time to discuss with potential clients the full range of benefits of hydronic systems as well as the price.

Contrary to common belief, comfort during the heating season is not solely determined by indoor air temperature. Comfort is achieved and maintained by controlling how the body loses heat. When interior conditions allow heat to leave a person’s body at the same rate as it is generated, that person feels comfortable. If heat is released faster or slower than the rate it is produced, some degree of discomfort is experienced.

A normal adult engaged in light activity generates heat through metabolism at a rate of about 400 Btu/hr. The body releases this heat through several processes, including convection, radiation, evaporation and conduction.

For indoor environments in colder weather, thermal radiation and convection typically account for almost 75% of the total heat output from the body. Heat loss by thermal radiation alone can be 50% to 60% of the total heat loss, especially within buildings that have cold wall, floor or ceiling surfaces.

Properly designed hydronic systems control the air temperature as well as the surface temperature of rooms to maintain optimal comfort. A hydronically heated floor or ceiling can raise the average surface temperature of rooms. Since the human body is especially responsive to radiant heat loss, these warm surfaces significantly enhance comfort. Proper indoor humidity is also easier to maintain in buildings using hydronic heating due to reduced air leakage.

Factors such as activity level, age and general health determine what a comfortable environment is for a given individual. When several people are living or working in a common environment, any one of them might feel too hot, too cold or just right. Heating systems that allow different zones of a building to be maintained at different temperatures can adapt to the comfort needs of several individuals. Hydronic heating systems are easy to zone using several different approaches.

See idronics #5 for a complete discussion on how to zone hydronic heating systems: idronics #5

ENERGY SAVINGS

Ideally, a building’s rate of heat loss would not be influenced by how that heat is replaced. However, evidence has shown that otherwise identical buildings can have significantly different rates of heat loss based on the types of heating systems installed. Buildings with hydronic heating systems have demonstrated a tendency for lower heat loss compared to equivalent structures with forced-air heating systems.

There are several reasons for this reduced heat loss. One is that hydronic systems, unlike forced-air systems, have very little effect on room air pressure while operating. The more significant changes in room air pressure created by forced-air systems can increase the rate of outside air infiltration or inside air exfiltration through the exterior surfaces. The greater the rate of air leakage, the greater the rate of heat loss.

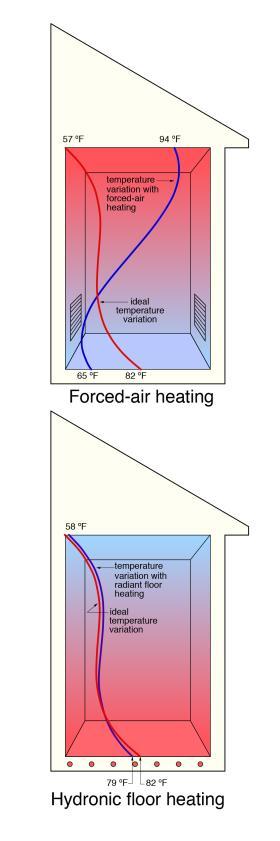

Another factor affecting building energy use is air temperature stratification (e.g., the tendency of warm air to rise toward the ceiling while cool air settles to the floor). Stratification tends to be worsened by high ceilings, poor air circulation and heating systems that supply air into rooms at high temperatures. Maintaining comfortable temperatures in the occupied areas of rooms plagued with a high degree of temperature stratification leads to significantly higher air temperatures near the ceiling. This increases heat loss through the ceiling.

Hydronic heat emitters that transfer the majority of their heat output by thermal radiation reduce, and in some cases eliminate, undesirable air temperature stratification. This reduces heat loss through ceilings and allows comfort to be maintained at lower air temperatures.

Figure 2-3 shows a comparison between the undesirable air temperature stratification created by forced-air systems operating with poorly placed registers versus the desirable “reverse” stratification created by hydronic radiant floor heating.

LOW DISTRIBUTION ENERGY

Properly designed hydronic systems use significantly less energy to move heat from where it is produced to where it is needed. A well-designed hydronic system, using a modern high-efficiency circulator, can deliver a given rate of heat transport using less than 10% of the electrical energy required by the blower of a forced-air heating system transporting heat at the same rate. This is a very important advantage of hydronic systems—one that can save thousands of dollars in operating cost over the design life of a typical residential heating system. This savings is often overlooked or not presented with sufficient emphasis by those who only consider the energy use associated with producing heat.

VERSATILITY

Modern hydronics technology offers virtually unlimited potential to accommodate the comfort needs, usage, aesthetic tastes and budget constraints of almost any building. A single system can be designed to supply space heating, domestic hot water and specialty loads such as snowmelting or pool heating. These “multi-load” systems reduce installation costs because redundant components are eliminated. They also improve the efficiency of boilers and reduce fuel usage relative to systems where each load is served by its own heat source.

Hydronic systems can combine a variety of heat emitters for space heating. For example, hydronic radiant floor heating may be used to maintain comfort in a basement, while the first and second floors are heated by panel radiators.

A wide variety of hydronic heat sources are available. They include boilers fired by gas, oil, electricity, firewood and pellets; geothermal and air-source heat pumps; solar collectors and devices that adapt to special circumstances or opportunities, such as “time-of-use” electrical rates or waste heat recovery.

CLEAN OPERATION

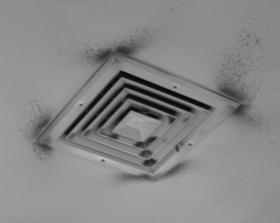

A common complaint about forced-air heating is its propensity to move dust and other airborne particles such as pollen and smoke throughout a building. In buildings where air-filtering equipment is either of poor quality or improperly maintained, dust streaks around ceiling and wall diffusers are often evident, as seen in Figure 2-8.

Eventually duct systems and other air-handling equipment require internal cleaning to remove dust and dirt that has accumulated over several years of operation, as seen in Figure 2-9.

In contrast, few hydronic systems involve forced-air circulation. Those that do create room air circulation rather than building air circulation. This reduces the dispersal of airborne particles and microorganisms. This is a major benefit in situations where air cleanliness is imperative, such as for people with allergies, health care facilities or laboratories.

QUIET OPERATION

Many people view their home as an escape from the noise and stress associated with modern life. As such, the home should provide “acoustical comfort” as well as thermal comfort. When it’s time to relax, noise from any heating or cooling system is certainly unwelcome. A properly designed and installed hydronic system can operate with virtually no detectable noise in the occupied areas of a home. These characteristics make hydronic heating ideal in sound-sensitive areas such as home theaters, reading rooms or sleeping areas.

NONINVASIVE INSTALLATION

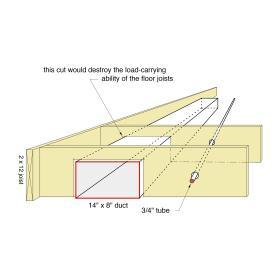

Consider the difficulty encountered when installing adequate and properly sized ducting within a typical wood-framed house. If the house happens to use open web floor trusses rather than traditional floor joists, the ducting may be able to be installed as shown in Figure 2-11.

However, most homes are not framed in this manner. Instead, they have solid floor joists. Making the cuts necessary to accommodate properly sized ducting in this type of framing would destroy its structural integrity.

This situation leads to ducts being installed in unconditioned attics or “hidden” behind interior soffits, as seen in Figure 2-12. Such situations can also result in undersized ducts or inadequate placement of ducts. Occupants eventually pay the price in terms of reduced comfort, noise, increased heat loss or compromised aesthetics.

By comparison, modern hydronic systems are easy to integrate into buildings without compromising their structure or the aesthetic character of the space. The reason for this is the high heat capacity of water. A given volume of water can absorb almost 3,500 times more heat as the same volume of air for the same temperature change. This means that the volume of water that must be moved through a building to deliver a given amount of heat is only about 0.03% that of air! This greatly reduces the size of the distribution “conduit.”

For example, a 3/4-inch diameter tube carrying water at 6 gallons per minute around a hydronic system operating with a 20ºF temperature drop transports as much heat as a 14” by 8” duct carrying 130ºF air at 1,000 feet per minute. Figure 2-13 depicts these two options, side by side, in true proportion.

Notching into 2 x 12 floor joists to accommodate the 14” by 8” duct would destroy their structural integrity. However, small-diameter flexible tubing is easily routed through the center of the same framing with negligible effect on structure.

Hydronic systems using small diameter flexible tubing are also much easier than ducting to retrofit into existing buildings. The tubing can be routed through closed framing spaces much like electrical cable, as shown in Figure 2-14.

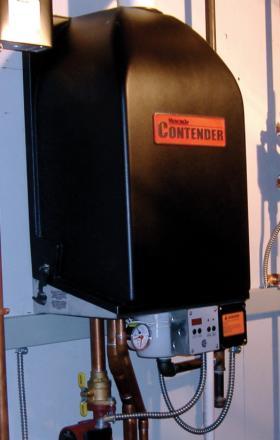

For buildings where utility space is minimal, small wall hung boilers can often be mounted in a closet or small alcove, as seen in Figure 2-15. In many cases, these compact boilers can supply the building’s domestic hot water as well as its heat. The entire “mechanical room” may have a footprint of less than 10 square feet.

ABILITY TO ZONE

The purpose of any heating system is to provide comfort in all areas of a building throughout the heating season. Doing so requires systems that can adapt to the lifestyle of the building occupants, as well as the constantly changing thermal conditions inside and outside of a building.

Imagine a building in which all rooms have the same floor area. Someone not familiar with heating system design might assume that each room, because they are all the same size, requires the same rate of heat input. Although such an assumption might be intuitive and simplistic, it fails to recognize differences in the thermal characteristics of the rooms. Some rooms might have only one exposed beyond these differences are conditions imposed by the occupants. One person might prefer sleeping in a room maintained at 63ºF, while another feels chilled if their bedroom is anything less than 72ºF. One occupant might prefer a living room maintained at 70ºF while relaxed and reading, while another wants the temperature in the exercise room at 65ºF during a workout.

The combination of room thermal characteristics, outdoor conditions and occupant expectations presents a complex and dynamic challenge for the building’s heating system as it attempts to maintain comfort.

One method that has long been used to help meet this challenge is dividing the building’s heating system into zones. A zone is any area of a building for which indoor air temperature is controlled by a single thermostat (or other temperature-sensing device). A zone can be as small as a single room, or it may be as large as an entire building.

Figure 2-16 shows a zoning plan for the first floor of a house. The living room, kitchen, half-bath and laundry are combined into a single zone. The master bedroom, master bathroom and closet form another zone. The garage is also treated as a separate zone.

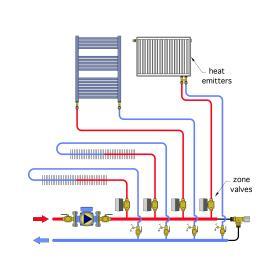

There are several ways to create zoned hydronic heating and cooling systems. All of these approaches are simpler and less expensive than equivalent zoning of a forced air system. Figure 2-17 shows part of a hydronic piping schematic in which zone valves are used to control the flow of heated water to each heat emitter.

Proper zoning accounts for differences in the activities that occur in different areas of a building, as well as differences in preferred comfort levels, interior heat gain and the desire to reduce energy use through reduced temperature settings (e.g., “setback”).

For a more in-depth discussion of modern zoning methods for hydronic systems: