PREFACE

All people instinctively desire warm water for washing. Throughout human history that desire has been met in many ways—from iron pots suspended over fires, to modern electronically-controlled tankless water heaters. A reliable source of clean and safe domestic hot water (DHW) is now a requirement in most buildings intended for human occupancy. The importance of domestic hot water in providing comfort, convenience and hygiene cannot be overstated. Delivering it remains one of the most important responsibilities of plumbing system designers.

idronics 11 idronics 11 provides an overview of the history of domestic water heating.

There are currently many options for heating domestic water, using almost any available fuel. Once the water is heated, the building’s plumbing system must deliver it to fixtures such as showers, tubs, sinks, dishwashers, clothes washers or other processes requiring hot water. The ability of different plumbing systems to deliver hot water efficiently and safely varies considerably. For example, a bathroom sink located 5 feet from a consistent source of domestic hot water would likely have heated water at an acceptable delivery temperature flowing from its tap within 2 seconds of opening the faucet. The same fixture located 75 feet from the hot water source may not receive hot water at the same acceptable temperature for 30 seconds or more after the faucet is opened. This delay between opening a faucet and having domestic hot water at an acceptable temperature flow from the fixture is undesirable from several standpoints:

First, it’s annoying to building occupants. People in most developed countries have become intolerant of waiting for expected results. They are accustomed to instant light at the flip of a switch, instant heat from the burner of a gas stove, and instant operation of an automobile when the key is turned or a button is pushed. It’s not surprising they expect instant hot water to flow from a hot water faucet. Second, the cool water that flows down the drain while hot water is making its way from the heat source to the faucet is wasted, as is the heat that this water once contained. Wasted fresh water (hot and cold) has become a major concern in many areas of North America where long-term drought conditions have worsened at the same time as population growth, and thus demand for fresh water, has accelerated.

Studies have shown that the average home wastes more than 3,650 gallons of heated water per year waiting for hot water at the desired temperature to arrive at fixtures.1 Assuming this wasted water was originally heated from 50 to 120ºF using electricity priced at $\$$0.15/kWhr, the wasted energy cost is about $\$$94 per year. This is in addition to the cost of the water itself. Furthermore, some of the heat dissipated from the hot water distribution piping into the building adds to that building’s cooling load, resulting in further energy costs.

Beyond the costs of wasted water and energy, it’s important to understand that some domestic hot water delivery systems can create conditions that allow pathogens, such as Legionella bacteria, to thrive. These pathogens represent a serious health threat. They are more likely to exist in domestic hot water delivery systems that contain piping where heated water could remain stagnant, in some cases for days. They can also develop in domestic hot water systems that are continually operated at reduced water temperatures—typically less than 140ºF at the heat source. These conditions create growth environments favorable to the bacteria.

If water containing these pathogens is discharged through fixtures such as showers, the mist created by the shower can be inhaled. This can lead to a serious and even potentially fatal disease. Thus, all domestic hot water delivery systems should be designed to minimize the potential for such pathogens to exist.

One of the best ways to minimize wasted water and energy in domestic hot water delivery systems is by circulating hot water through the system at times when it would otherwise not be moving because of no demand at the fixtures. Such systems are called “recirculating” domestic hot water systems. They are the principal focus of this issue of idronics.

CONCEPT OF A RECIRCULATING DHW SYSTEM

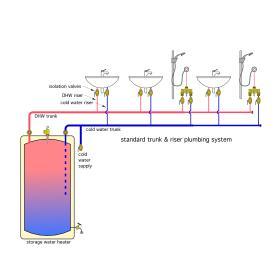

Figure 1-2 shows a simple trunk and branch plumbing distribution system that supplies hot and cold water to three lavatories and two showers. Domestic hot water is supplied from a tank-type water heater to the hot water trunk. It flows along the trunk piping and eventually into a “riser” that leads to the fixture with the demand. Once that demand stops, hot water flow also stops in all portions of the system. The water in the trunk and risers cools as heat is dissipated from the piping.

If another demand for DHW occurs within a few minutes, and through the same portion of the distribution system, the water temperature in that piping may have only decreased a few degrees, especially if the piping was well insulated. The temperature at which it emerges from the fixture may be suitable within 3 or 4 seconds of opening the faucet. This scenario is probably acceptable to the person using the fixture.

However, if there is no demand for DHW through the piping for longer periods of time, perhaps an hour, or overnight, the water will have cooled substantially. When a DHW demand occurs, it will take substantially longer— perhaps 30 seconds or more depending on pipe sizes, length of flow path, and air temperature surrounding the piping—before DHW at the desired temperature flows from the fixture. This can annoy the person waiting for the anticipated comfort of the hot water at a desirable temperature. It also wastes most of the water between the heat source and fixture.

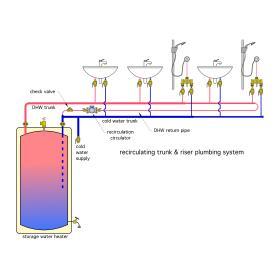

Figure 1-3 shows how the standard system of Figure 1-2 can be modified to include recirculation. The system now includes a small recirculation circulator and a pipe that brings hot water not drawn off at a fixture back to the heat source. The hot water piping now forms a complete circuit with the heat source, as compared to the “one-way” path for hot water in the traditional trunk and branch system of Figure 1-2. Each fixture is supplied by a short “riser” pipe from the hot water trunk. This riser should be as short as possible to minimize the water volume not contained within the recirculating circuit.

The end of the hot water supply piping connects to a reduced-size return pipe, which leads back through the circulator to the heat source. A check valve is installed in this return pipe to ensure that cold water cannot flow backward towards the hot water risers. The size of the return pipe is smaller than the hot water supply pipe. This is possible because the return pipe is not responsible for carrying hot water to any fixture. It only has to carry sufficient flow to compensate for the heat loss of the hot water supply piping—a quantity that can be calculated based on information given in a later sections.

The recirculation circulator must be compatible with fresh water. Any wetted components within that circulator must be made of bronze, stainless steel or a suitable engineered polymer. These components must also conform to the no-lead requirement that applies to all domestic water plumbing components within the United States. In some systems, the recirculation circulator operates continuously (24/7). In other systems, it runs based on a timer with specific user-set on-times and off-times; the off-times typically are overnight hours, or times when the building has little, if any, need for DHW throughout its plumbing system.

The circulator might even operate automatically based on “learned” DHW usage patterns that have been sampled over several days. In any case, the objective is to ensure that hot water is immediately available at the fixtures based on some criteria that are acceptable to the building occupants, and if possible, reduce electrical use by turning the circulator off at other times.

The system shown in Figure 1-3 is very simplified. It does not include the components necessary to ensure that domestic hot water at potentially high temperatures doesn’t reach the fixtures, nor does it ensure that stable temperatures are maintained within the recirculation circuit. The components and details necessary for these functions are discussed in section 2, as well as in later sections of this issue of idronics.