Balancing valves must be protected from dirt and debris. This section details how to best keep any of the valves in this issue operating at peak efficiency.

Optimal Performance Over Time

For a balancing valve to perform well over time, maintenance is required. Balancing valve orifices need to remain clean. If these orifices accumulate debris, the precision operation of the valve is compromised.

A central dirt and magnetic particle separator should be specified in any system containing balancing valves.

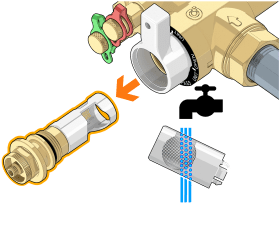

The Caleffi FLOWMATIC® Express coil kit contains a removable/washable debris screen, as shown in Figure 6-1. This screen supplements the function of a central dirt/magnetic particle separator.

Dirt Separators and Y-Strainers

While it may seem redundant to include two dirt separation devices in a system, they serve different roles. Central dirt separators are best for capturing large amounts of system debris from the flow stream without increasing the pressure drop across the separator as the debris accumulates. A collision media in a dirt separator removes particles down to 5 micrometers in size. Unlike a filter or Y-strainer that traps debris in the flow path, Caleffi dirt separators operate based on slowing the fluid’s velocity. When debris collides with the separation media, it falls to the bottom portion of the separator body, out of the flow path. This prevents the differential pressure across the separator from increasing as debris is collected.

Strainers within components, such as the FLOWMATIC Express coil kit, are best applied as a last defense for small amounts of system debris that may be downstream of the central dirt separator. However, if the central dirt separator was omitted, these small strainers could partially or completely plug and drastically limit flow through the branches. A best practice is to flush a system of as much system debris as is possible before any control valve is commissioned. The Caleffi coil kit includes valves that allow the system fluid to bypass the terminal unit when the system is first flushed. This minimizes the potential of debris becoming lodged in the terminal unit.

For more background on dirt separation strategies in hydronic systems, see idronics #15.