Significantly lower installation cost

Air-to-water heat pumps can be typically be installed at costs of 30 to 50% those of equivalent capacity and unsubsidized geothermal heat pump systems. The latter require extensive excavation (for installing horizontal earth loops) or extensive drilling (for installing vertical earth loops). Although costs vary regionally and with specific site conditions, current estimated vertical earth loop installation costs range from about \$2,000 to \$3,500 per ton of heat pump capacity. At an average of \$2,750 per ton of capacity, a typical 4-ton rated vertical earth loop field would cost \$11,000. This is exclusive of the heat pump and any other interior portion of the system. In contrast, a typical air-to-water heat pump is installed on a small support stand adjacent to the building is serves. The total exterior installation cost, excluding the heat pump, is likely in the range of \$500-800. The cost of the geothermal earth loop is eliminated, and thus a major portion of the installation cost associated with a geothermal heat pump is avoided.

Noninvasive installation

Installing geothermal earth loops is highly disruptive to existing landscapes. Although the equipment needed for horizontal and vertical earth loop installations is available in most areas of North America, the use of that equipment, especially on established landscapes, if very invasive. Complete restoration of established landscapes can take weeks or months. The cost of such restorations should be included as part of the geothermal heat pump installation.

Ground water protection

Laws intended to protect ground water can impact the installation of geothermal earth loops. Deep boreholes have the potential to reach ground water aquifers. Surface runoff or spillage of potentially toxic materials during installation is a possibility, as is surface seepage into boreholes that are not properly sealed. Although proper techniques minimize these threats, they should be evaluated and factored into the logistics and cost of earth loop installations. These factors are not present when an air-to-water heat pump is installed.

After installation there remains a possibility, albeit small, that the earth loop could be damaged by future excavations. Although obviously unintentional, these situations have occurred due to lack of accurate mapping of where the buried piping is located. Spillage of the antifreeze solution from ruptured piping into surrounding soil is possible. When non-toxic antifreeze such as propylene glycol is used, it’s unlikely that such spillage would warrant emergency actions. However, methyl alcohol and ethylene glycol, both of which have been used as antifreezes in earth loop systems, are toxic materials. Spillage of many gallons of these materials could require legally mandated remediation.

Independent of incentives

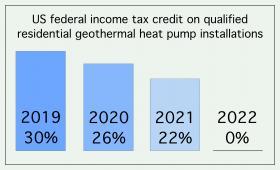

In most areas of the U.S. and Canada, air-to-water heat pumps are not currently subsidized through utility or government incentives. This is in contrast to geothermal heat pump systems, which are significantly subsidized in many areas of North America. Although the availability of government incentives that underwrite a significant portion of the installation of geothermal heat pumps seems like a decisive advantage, it is a temporary condition that artificially skews the market.

As this issue of idronics is being written, the U.S. federal income tax credit on geothermal heat pump systems stands at 26% of qualified geothermal equipment installation cost. This is down from 30% in 2019. Current tax law will reduce this credit to 22% through the end of 2021. At that point, barring legislation that would extend these tax credits, they will end. The phaseout of these tax credits will significantly increase the installed cost and decrease the economic merit of geothermal heat pump systems relative to alternatives. This will improve the life cycle economics of air-to-water compared to those of geothermal heat pumps.

Higher net COP

Both geothermal water-to-water heat pumps and air-to-water heat pumps should be evaluated based on "net COP" rather than the COP of the heat pump as a standalone device. Net COP is calculated by dividing the rate of heat output by the total electrical power required to run the heat pump and its associated circulators. Net COP is a better indicator of the true operating cost of either type of hydronic heat pump since the power required by the required circulators is factored in.

For a geothermal water-to-water heat pump, this would include the circulator(s) used to create flow in the earth loop and the circulator that provides flow through the load side of the heat pump. Some earth loops require multiple circulators connected in series to provide sufficient head and flow. The total power required by these circulators can be several hundred watts. Both the geothermal water-to-water heat pump and an air-to-water heat pump require a load side circulator.

To see the effect of net COP, consider a geothermal water to water heat pump with a heating capacity of 48,000 Btu/hr. The heat pump compressor draws 4.2 KW when operating. Its earth loop requires two circulators, piped in series, operating at 220 watts each. The load side circulator draws 180 watts. Calculate the COP of the heat pump itself, and the net COP of the heat pump with its associated circulators.

The COP of the heat pump as a standalone device is:

$$COP_{HPonly}={ {48,000 Btu / hr\over [4200] watt · 3.413 {Btu / hr\over watt}}}= 3.35$$

The net COP of the heat pump and its associated circulators is:

$$COP_{net}={ {48,000 Btu / hr\over [(2 · 220) +4200 + 180] watt · 3.413 {Btu / hr\over watt}}}= 2.92$$

In this example, the net COP is about 13% lower than the COP of the heat pump as a standalone device.

Assume that an air-to-water heat pump has an output of 48,000 Btu/hr, with a corresponding electrical input of 5.5 KW. The load side circulator requires 180 watts. Calculate the COP of this heat pump alone and the net COP of the heat pump and its load side circulator.

The COP of the air-to-water heat pump alone is:

$$COP_{HPonly}={ {48,000\, Btu / hr\over [5500]\,watt · 3.413 {Btu / hr\over watt}}}= 2.56$$

The net COP of the heat pump and its load side circulator is:

$$COP_{net}={ {48,000\, Btu / hr\over [5500 + 180]\,watt · 3.413 {Btu / hr\over watt}}}= 2.48$$

In this example, the net COP is only about 3% lower than the COP of the air-to-water heat pump as a standalone device. Even though the air-to-water heat pump draws an additional 1.3 kilowatts of electrical power compared to the geothermal heat pump, its net COP, in this example, is only about 12% lower than that of the geothermal heat pump. It’s also important to remember that the COP of any heat pump is highly dependent on its operating conditions, and thus, there are scenarios where the net COP of an air-to-water heat pump could exceed the net COP of a geothermal water- to-water heat pump.

Savings decrease as loads decrease

As the design heat loss of buildings decreases, so do the energy cost savings associated with a heat pump system having a “high” seasonal COP relative to those of a heat pump system with a “lower” COP. The seasonal COP of a heat pump is a weighted average value that accounts for the wide range of operating conditions that a specific heat pump undergoes during an entire heating season, in a specific system at a specific location. Seasonal COP is typically estimated using computer simulation and is discussed in more detail in section 5. Formula 3-1 can be used to calculate the annual heating energy reduction realized when a heat pump with a higher seasonal coefficient of performance is used instead of a heat pump with a lower seasonal coefficient of performance.

Formula 3-1

$$E_{s}=E_{R}\,[{ {1\over COP_{L}}-{1\over COP_{H}}]}$$

Where:

Es= energys savings(MMBtu/yr)

ER = seasonal space heating energy required by building (MMBtu/hr)

COPL = seasonal average coefficient of performance of lower-performing heat pump

COPH = seasonal average coefficient of performance of higher-performing heat pump

Consider a 2,000 square foot house with a design heating load of 15 Btu/hr/ft2. The design heating load is 30,000 Btu/hr. Assume that this load corresponds to an interior temperature of 70ºF and an outdoor design temperature of 5ºF. The house is located in a relatively cold 6000ºF•day climate. It’s estimated annual space heating energy requirement is 39.9 MMBtu/yr (1 MMBtu = 1,000,000 Btu). The house is equipped with a lowtemperature hydronic heating distribution system. A computer simulation of a geothermal water-to-water heat pump systems indicates an average seasonal COP of 3.4. Another simulation for a low ambient airto-water heat pump system projects a seasonal COP of 2.5. Estimate the annual energy saved by using the geothermal heat pump rather than the air-to-water heat pump. Also estimate the cost savings assuming that the local cost of electricity is $0.11 per kilowatt-hour.

The energy saved is easily calculated using Formula 3-1:

$$E_{s}=E_{R}\,[{ {1\over COP_{L}}-{1\over COP_{H}}]}= 39.9[{{1\over2.5}-{1\over3.4}}]=4.22 MMBtu/season $$

If the air-to-water heat pump was used, the additional 4.22 MMBtu/season required would have to be supplied by electricity. At a flat rate of $0.11 per KWHR the additional energy would cost:

$$4.22 MMBtu\,({ {293KWHR\over MMBTU})({\$0.11\over KWHR})}= \$136/season$$

This is certainly a non-trivial savings, especially considering that it is a recurring annual cost that could escalate if the price of electricity increases. However, this energy cost should also be considered in the context of spending several thousands of dollars more to install the geothermal heat pump earth loop, especially after installation subsidies are no longer available. Based on a previously mentioned cost estimate, a vertical earth loop for a 2.5-ton rated geothermal heat pump would cost between \$5,000 and \$8,750. At an average estimated cost of \$6,875, an annual savings of \$136 would yield a simple payback of 50.6 years. That is about twice the life expectancy of current generation geothermal heat pumps.

This example demonstrates that even though the geothermal heat pump has a higher seasonal COP compared to the air-to-water heat pump — 36% higher in this case — the annual energy cost savings of operating the geothermal heat pump in a modern energy-efficient house is such that the higher installed cost cannot be recovered in a reasonable time. This example is not meant to imply that similar economic results occur in all situations. Each must be evaluated based on specific heating loads, estimated performance for the installed systems and local cost of electrical energy.

It should also be mentioned that cooling costs were not factored into this comparison since the location was assumed to be a relatively cool climate with minimal cooling requirements. Any cooling load would be met at a slight lower cost by the geothermal heat pump compared to the air-to-water heat pump, but the associated savings would be very small.

Influence of global markets

Although they currently represent a small portion of the heat pump market in North America, air-to-water heat pumps are widely used in Asia and Europe.

The Japanese publication JARN reported that the European market for air-to-water heat pumps reached 368,900 units in 2018, which represented a 14.3% increase over the previous year. France and Germany are the two largest markets. Split system air-to-water heat pump configurations represent about 70% of the overall market. Several European companies that are well known as boiler manufacturers have made significant investments in air-to-water heat pump technology and now offer a range of products.

JARN also reported the following number of air-to-water heat pump installations during 2018: China, 1,280,000 units, and Japan, 475,000 units.

Heat pump sales in Europe are incentivized by directives aimed at carbon reduction. In China there are also incentives aimed at converting coal-fired heating systems to electricity.

JARN did not report an estimate for the number of airto-water heat pumps (for space heating and cooling applications) for the U.S. or Canada. The number of airto-water heat pumps installed for building heating and cooling in the U.S. and Canada during 2018 is very small in comparison to the European and Asian market, perhaps under 1,000 units. Still, past trends indicate that many aspects of hydronics technology migrate from Asian and European markets into North America.