Although dedicated heat pump water heaters are used for most domestic water heating applications and have been the primary focus of this issue, there are situations where other types of heat pumps, primarily intended for space heating or cooling, can be adapted to domestic water heating as an ancillary load. This section discusses some of the possibilities.

Air-To-Water Heat Pumps Used For Domestic Water Heating

One of the fastest growing segments of the global heat pump market is based on units that extract heat from outside air and transfer it to water or an antifreeze solution. Although these heat pumps are generally intended for space heating and cooling, they can also provide domestic water heating as an ancillary load. Using them in this manner helps provide a more complete HVAC offering in typical residential applications (e.g., space heating, cooling and domestic water heating).

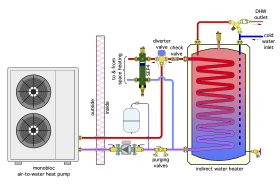

Figure 5-1 shows an example of a monobloc air-to-water heat pump connected to an indirect water heater tank. A heat exchanger within the tank separates a non-toxic antifreeze solution that passes through the heat pump from the potable water in the tank.

In a typical application, a motorized 3-way diverter valve directs the flow of hot fluid from the heat pump to either the heat exchanger within the indirect water heater tank, or to other parts of the system intended for space heating.

In this application, it is imperative to use an indirect water heater with a larger internal coil heat exchanger. The greater the surface area of this heat exchanger, the lower the fluid temperature exiting the heat pump can be, while still transferring the heat pump’s full heat output to the water within the indirect water heater. Lower operating temperatures increase the heating capacity and COP of the heat pump.

If no suitable tank can be sourced, it is possible to use a properly sized external stainless steel heat exchanger in combination with a standard thermal storage tank.

When domestic hot water temperatures of 130ºF or more are required, the domestic hot water leaving the indirect tank can be routed through an auxiliary heater to boost its temperature as necessary.

Some air-to-water heat pumps have internal controls that monitor the temperature of the indirect water heater, and automatically operate the diverter valve and the heat pump’s refrigeration system whenever a call for domestic water heating is present. These controls can also be configured to allow the domestic water heating load to have temporary “priority” over space heating (or cooling) when there are simultaneous calls from both loads.

See idronics 27 and idronics 30 for more information on air-to-water heat pump systems.

Water-To-Water heat Pumps Used For Domestic Water Heating

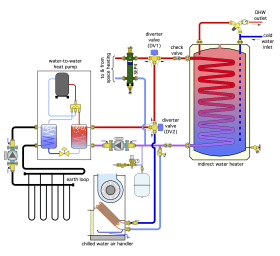

Geothermal water-to-water heat pumps can also be configured to provide domestic water heating as an ancillary load. The piping can be similar to that used for an air-to-water heat pump, as shown in Figure 5-2.

Unlike the monobloc air-to-water heat pump system shown in Figure 5-1, antifreeze is typically not required between the water-to-water heat pump and the indoor portion of the system.

The system in Figure 5-2 has been expanded to include chilled water cooling using an air handler. A second diverter valve (DV2) directs flow from the heat pump to either a heating load (e.g., space heating or domestic water heating) or to cooling. Diverter (DV1) directs heated water to either the indirect water heater or to space heating.

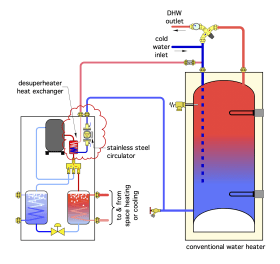

Some geothermal water-to-water heat pumps can also be equipped with “desuperheater” heat exchangers, which transfer heat from hot refrigerant leaving their compressor to a circulating stream of domestic water. Figure 5-3 shows the concept.

See idronics 9 for more information on geothermal heat pump systems and idronics 13 for more information on chilled water cooling.

Heat Recovery Applied To Domestic Water Heating

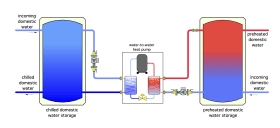

Water-to-water heat pumps can also be applied in heat recovery applications. An ideal scenario is an industrial process where both chilled fluid and domestic hot water are needed at approximately the same time. One example would be producing a product such as gelatin. This process requires both ice and hot water. The energy used to produce the ice is reduced by any device or process that can cool incoming domestic water ahead of the icemaker.

Likewise, the energy required for hot water is reduced by any device or process that can preheat the incoming cold domestic water. A water-to-water heat pump can do both of these processes simultaneously. The concept is shown in Figure 5-4.

The effective COP of the heat pump in this type of application can be very high. The reason is that both the chilled water and preheated domestic water are useful outputs that displace what would otherwise be additional energy input to produce the same output streams using separate heating and cooling devices. In theory, the effective COP of the water-to-water heat pump in these applications would be:

Formula 5-1:

$$ COP_{e}= (2 \ X \ COP_{HP}-1) $$

Where:

$$ COP_e = \text {effective COP of the heat pump system in this application} \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ \ $$

$$ COP_{HP} = \text {COP of the heat pump at the operating conditions imposed by the two entering water streams} $$

For example, a heat pump operating with a COP of 3.0 in a heat-recovery application where both output streams are useful would be:

$$ COP_{e}=(2 \ X \ COP_{HP}-1)=(2 \ X \ 3 -1)=5 $$